Description

As a traditional form of infusion packaging, glass bottle infusion has many inherent disadvantages, such as the necessity to form an air circuit during clinical infusion, which increases the risk of secondary contamination; glass bottles are bulky, occupying space, and have high transportation costs. However, glass bottle infusion also has many advantages. For example, glass bottles exhibit good stability among all forms of infusion packaging, with excellent barrier properties such as waterproofing, oxygen barrier, light barrier, and oxidation resistance. They also have stable compatibility with medicinal solutions. Therefore, many medicinal solutions, especially nutritional and therapeutic infusions, are currently packaged in glass bottles. Consequently, glass bottle infusion will occupy a certain share in the entire infusion field and will continue to have long-term value and prospects.

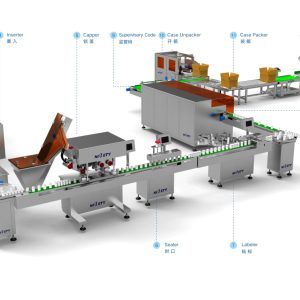

Under the leadership of Mr. Luo Guoqiang, who is known as the “Father of Large Infusion”, Huiyi Pharmaceutical Machinery has developed a new generation of automatic production line for large infusion in glass bottles in China. The equipment linkage production line mainly consists of bottle washing, filling, capping, crimping, bottle loading and unloading, and labeling stations. This production linkage line is highly favored by customers due to its high starting point, reliable design, stable performance, high efficiency, and low operating costs. Most large infusion manufacturers in glass bottles across the country have “Huiyi Manufactured” large infusion production lines in glass bottles. In the past three years, the market share of high-speed large infusion lines in glass bottles has reached over 80%.

Performance characteristics:

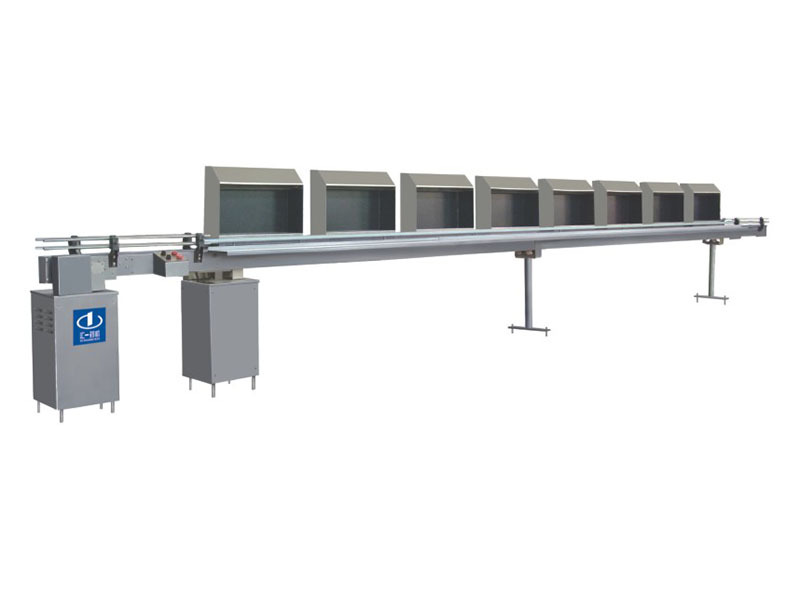

1. The bottle washing machine adopts a new type of structure (flexible selection of drum bottle washing, vertical bottle washing, or box-type bottle washing), with rough washing and fine washing completely separated and completed on two different machines, respectively, to avoid cross-contamination;

2. The box-type bottle washer adopts a secondary bottle receiving technology for bottle discharge, which avoids undesirable phenomena such as bottle toppling, overturning, and bursting during the discharge process, enhances the stability of the equipment, and mitigates the impact of excessive manual assistance on the production environment;

3. The box-type bottle washing machine adopts a caterpillar-type bottle carrier, and uses bottle mouth positioning technology for rinsing. After rinsing, there is a relatively long water pouring station, which ensures a long pouring time and no residual water in the bottle;

4. The vertical bottle washing machine adopts an interlocking robotic arm, which grips the bottle firmly without dropping it and has good durability. It uses a compression spring return mechanism to avoid the poor durability issue of tension spring robotic arms. The bottle washing nozzle is driven by a servo motor for tracking and rinsing, ensuring accurate tracking position, good nozzle alignment, and adjustable tracking range, thus avoiding the issue of mechanical cam wear causing gaps.

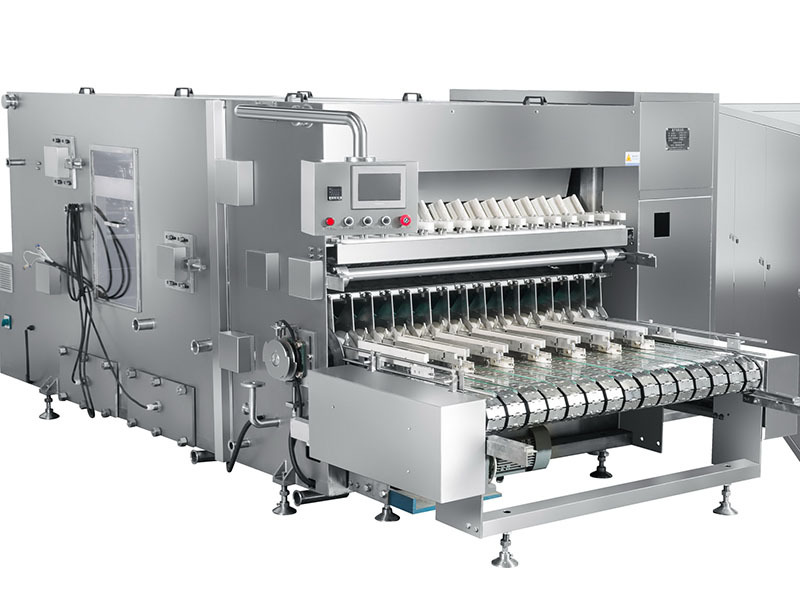

5. The filling machine utilizes the time and constant flow principles for filling, with the filling volume adjusted and metered accurately through a computer. It achieves no-bottle-no-filling, completely avoiding the defects of the funnel type, and can realize Cleaning in Place (CIP) and Sterilization in Place (SIP);

After filling, nitrogen filling treatment (ordinary nitrogen filling and vacuum nitrogen filling) can be carried out as needed. During the vacuum nitrogen filling and stopper pressing process, it is controlled by an electromagnetic valve: continuously switching between nitrogen filling and vacuuming, vacuuming the glass bottles, and then filling nitrogen after achieving vacuum. This process is repeated three times to achieve pure nitrogen filling of the infusion bottle’s internal space, protecting the medicinal solution and keeping the residual oxygen content below 1.0%;

7. The capping machine is equipped with a dust suction device, which can suck up the aluminum scraps generated during capping and then discharge them in a centralized manner;

From the end of precision washing and bottle discharge to the completion of capping, an online monitoring system is equipped to monitor key factors affecting product quality (such as dust particles, floating airborne dust and bacteria, wind speed, wind pressure, etc.), and the results can be printed online.

The entire production line features high automation, reasonable structural design, good reliability, fewer operating personnel, low labor intensity, good equipment versatility, and easy replacement of specifications and maintenance.