Description

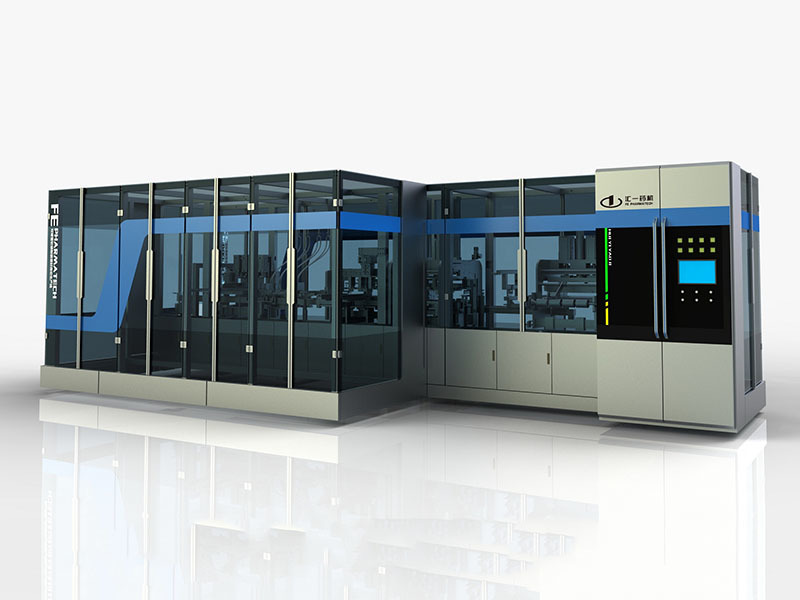

Product Name: Soft Bag Large Infusion Automatic Production Line Product Code: 1083318041094803456

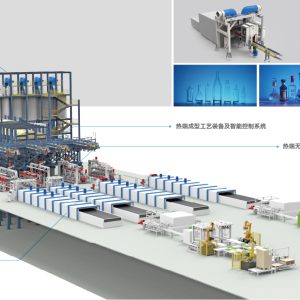

Based on years of design, manufacturing, and operational experience, as well as the assimilation of similar equipment technologies from both domestic and international sources, Hunan Huiyi Pharmaceutical Machinery Co., Ltd. offers an automatic production line for the integrated bag-making, filling, and sealing of non-PVC film soft bags for large infusion solutions. This production line not only significantly reduces the overall length but also enhances automation, stability, reliability, and production efficiency. It stands at the forefront of similar international products, replacing previous imported products while meeting the needs of various manufacturers. It can serve as an optional equipment for newly established pharmaceutical factories and as a replacement for existing ones undergoing renovation.

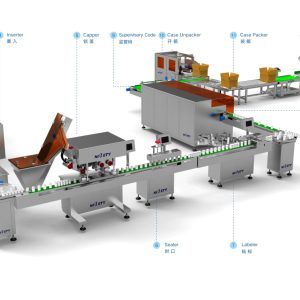

The non-PVC film soft bag infusion solution production line is a new and efficient production line, representing an upgrade from existing soft bag production lines. It can automatically complete processes such as printing, bag making, filling, and sealing.

Compared with similar domestic products, it has the following notable advantages:

1. High production efficiency, good stability, and low failure rate.

2. The production line is an integrated bag-making and filling machine with a length reduced by 1/3, resulting in a reduction of workshop area and air conditioning purification area by 1/3, thereby significantly reducing investment and operational costs.

3. Ensure 100% utilization of packaging materials to reduce the depletion of energy resources.

4. The production line structure has been simplified, resulting in more stable and reliable performance. For example, the removal of the bag transfer process has greatly improved the reliability of the production line compared to the original one.