Description

Product Name: Plastic Bottle Infusion Automatic Production Line Product Code: 1083318071092465664

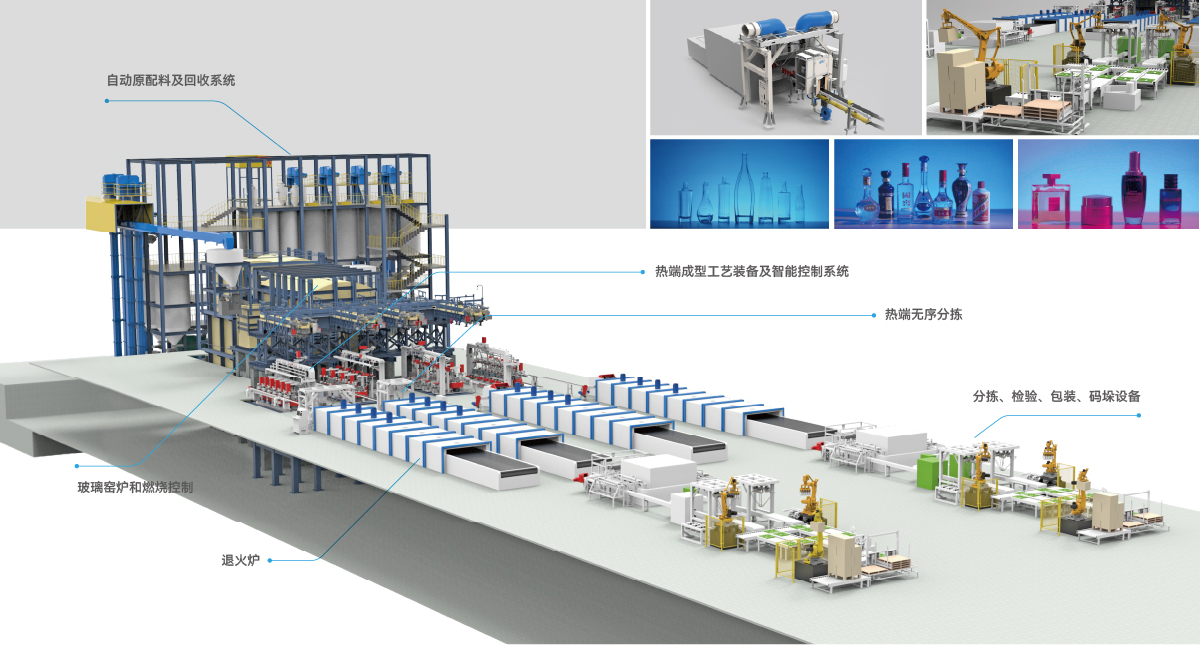

The plastic bottle infusion automatic production line consists of a plastic injection molding machine, a two-step blow molding machine, and a washing, filling, and sealing integrated machine. The production process mainly involves injecting plastic pellets into preforms through an injection molding machine, heating the preforms through far-infrared radiation, and blow molding them into bottles using a bi-directional stretching blow molding process. Finally, the formed bottles are washed, filled, and sealed through a washing, filling, and sealing linkage line.

Compared with similar domestic products, it has the following significant advantages:

1. High production efficiency, good stability, low failure rate, and low energy consumption.

2. The heating light box of the bottle blowing machine is designed with a three-dimensional multi-layer heating lamp tube heating method, which can control the temperature of different parts of the bottle preform, maximize the control of the temperature of the bottle preform in different heating stages, ensure that the bottle preform is fully and uniformly heated, and improve the quality of bottle blowing and the transparency of the bottle.

3. The stretching and forming mechanism of the bottle blowing machine adopts high-pressure stretching and blow molding, and the mold closing adopts oil-free airbag locking technology, which has a large locking force, less force on the elbow joint operation, and a long service life.

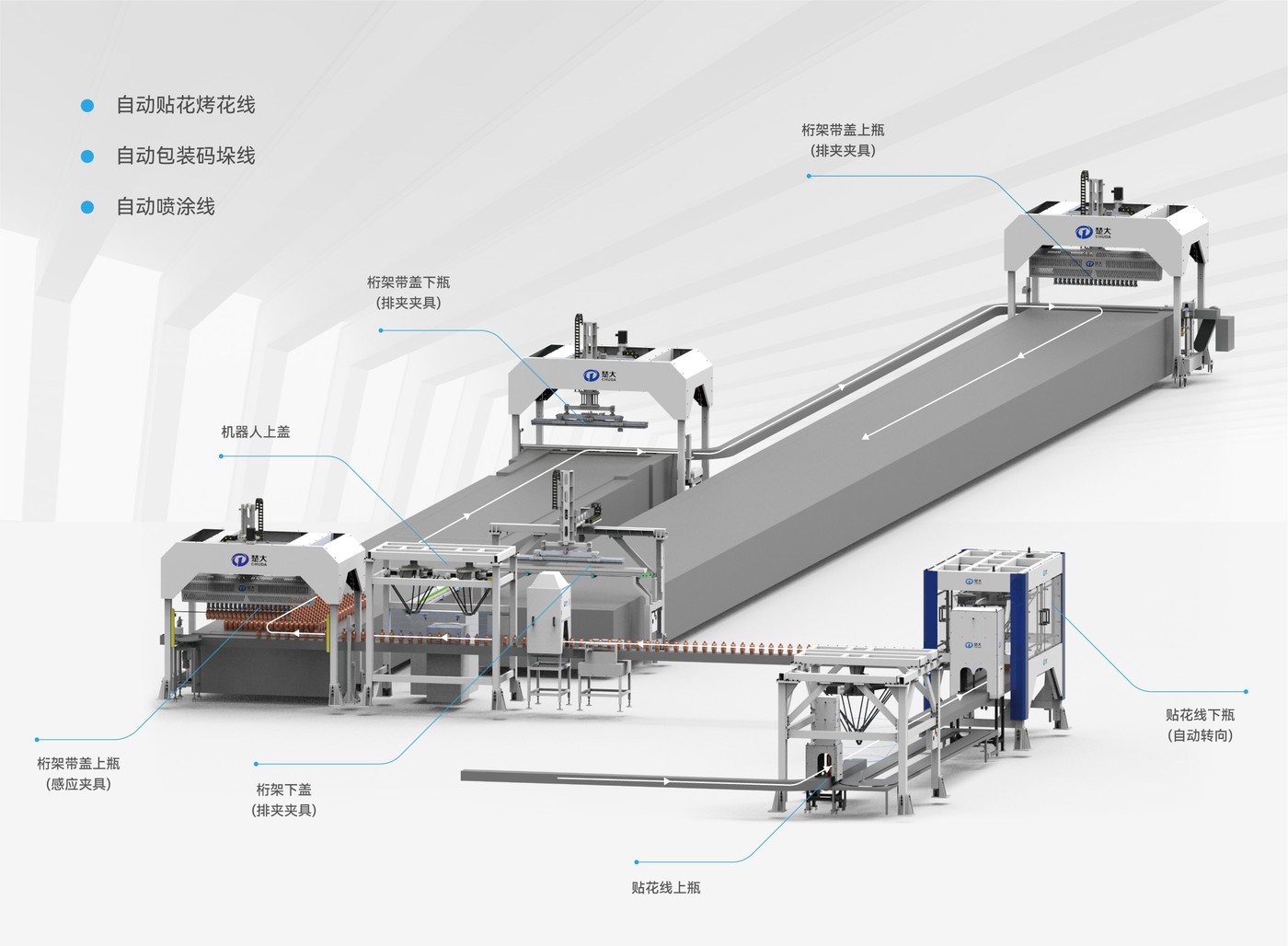

4. The bottle blowing machine can be automatically connected to the subsequent washing, filling, and sealing linkage line.

5. The bottle washing method of the washing, filling and sealing linkage line is flexible (can be air washed, water washed or mixed with air and water), and the negative ion generation device using air washing has a failure alarm function to reliably ensure the bottle washing effect.

Before sealing the washing, filling and sealing linkage line, a bottle mouth drying device and a bottle mouth pre pressing device are configured to facilitate the quality of sealing and welding;

7. Before welding the lid of the washing and sealing linkage line, there is an exhaust device inside the bottle, and the exhaust volume can be adjusted to ensure the quality of the bottle shape after sterilization;

8. The washing, filling and sealing linkage line has functions such as no bottle filling and no cap delivery; In addition, when changing specifications, the linkage line does not need to replace specification parts;