Description

Product Name: Antibiotic Bottle Washing, Drying, Filling and Blocking Linkage Production Line Product Code: 1083318129531703296

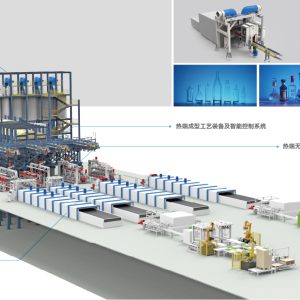

The antibiotic bottle washing, drying, filling and plugging linkage production line consists of three single machines: CLQ ultrasonic vertical cleaning machine, RSM sterilization and drying machine, and KGYX filling and plugging machine. It is divided into three working areas: cleaning, drying and sterilization, and filling and sealing. The units can be produced in linkage or used alone. The equipment is suitable for the production of antibiotic bottles with a specification of 2-25ml; The linkage line can automatically complete multiple processes such as antibiotic bottle watering, ultrasonic washing, blowing compressed air, flushing circulating water, blowing compressed air, flushing fresh water, blowing compressed air, preheating, high-temperature sterilization, cooling, bottle sorting, filling, plug sorting, plug pressing, and tray loading.

Performance characteristics:

1. The vertical bottle washing machine adopts a mechanical arm to clamp bottles, suitable for various specifications of antibiotic bottles;

2. The bottle cleaning adopts the method of reciprocating tracking and insertion of water vapor spray needle, utilizing the principle of ultrasonic cleaning and alternating water vapor spray flushing, which has good cleaning effect and saves energy; The equipment is equipped with a needle holder anti shake device to ensure the accuracy of needle insertion, low bottle breakage rate, and wide versatility.

3. The sterilization dryer is a whole tunnel structure, divided into three parts: preheating zone, high-temperature sterilization zone, and cooling zone. Using the principle of laminar disinfection with hot air to sterilize and remove heat from containers.

4. The sterilization dryer can be equipped with a circulating water cooling device and an automatic pressure balance adjustment system, which does not consume room air volume, reduces the risk of pressure imbalance between the room and the oven, and has a good cooling effect.

5. The sterilization dryer belt can be equipped with ultrasonic and CIP online cleaning systems, and the oven can be subjected to high-pressure water flushing from all directions and angles.

6. The filling and capping machine adopts a fully servo driven bottle conveying, linear tracking filling and linear capping method, which can automatically complete processes such as bottle sorting, bottle feeding, empty bottle weighing, filling, post filling weighing, capping, capping, non-conforming product removal, and bottle discharge.

1. The filling and plugging machine adopts a peristaltic pump for filling, and the equipment has functions such as no filling without bottles, no plugging without bottles, and automatic removal of inaccurate filling volume. The equipment has high operating accuracy and automatic adjustment, realizing programmed adjustment. When switching between multiple varieties, the program control and automatic adjustment are basically not affected by manual labor, avoiding opportunities for cross contamination.