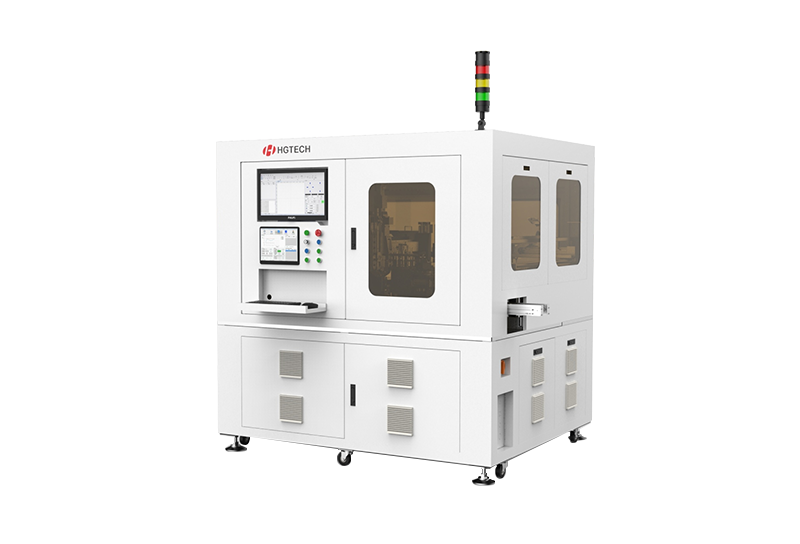

Description

Targeting mobile phone FATP assembly enterprises, we achieve automatic completion of TPU protective cover loading and unloading, assembly, testing, sorting and other processes in the mobile phone FATP assembly process, replacing manual operation and achieving high production efficiency

design capacity

350pcs/h

Drawing accuracy

±0.1mm

control mode

Touch screen+PLC; IPC

Product advantages

01

High precision

High precision displacement sensor positioning, with a positioning accuracy of ≤± 0.1mm

02

featured

Multi process highly integrated, including functions such as loading and unloading, testing, assembly, sorting, etc

03

High flexibility

High degree of flexibility, can directly connect with the manufacturer’s assembly line

04

High compatibility

The product fixture is replaceable and compatible with products of different specifications

Technical Parameter

Main technical parameters of the project

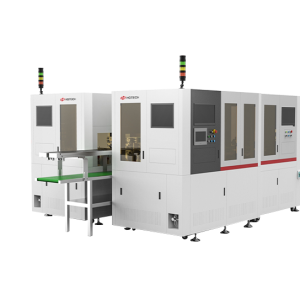

Model parameters, process and main functions, protective cover feeding TP feeding TP pulling test TP assembly cutting

(Determine process technology based on customer URS)

Design production capacity of 350pcs/h

Drawing parameters: Drawing force of 10N, continuous drawing time of 1s

Drawing accuracy ± 0.1mm

Protective cover feeding method: Material bin feeding (self-made)

Control method: touch screen+PLC; IPC

Environmental power supply specification: AC220V/50Hz, ± 5%

Environmental requirements: 0-35 ℃

Other overall dimensions (length x width x height) 1750 x 1500 x 1800mm