Description

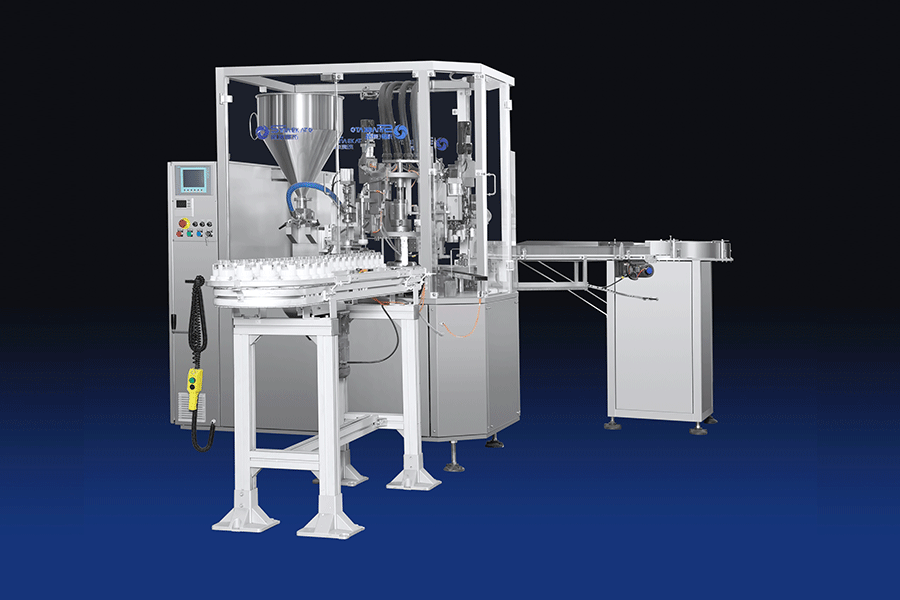

Fully Automatic Cream Filling Machine

Product Description

This machine is suitable for filling various creams and is widely used in the cosmetics, daily chemical, pharmaceutical, and food industries. Its integrated filling and capping system, coupled with a PLC touchscreen control system, ensures precise and efficient filling, ensuring leak-free and spill-free operation.

Performance Characteristics

1. Utilizing a Mitsubishi PLC control system, it integrates electrical, pneumatic, and mechanical functions, resulting in a compact size, low noise, and easy conversion. All parts that come into contact with the product meet FDA standards.

2. Speed: Up to 60 bottles/minute (with integrated filling and capping), depending on the viscosity of the product, bottle diameter, height, filling volume, and other optional features.

3. This machine utilizes centrifugal filling to ensure that the material adheres to the bottle wall, eliminating the problem of product oxidation caused by incomplete filling.

4. It uses a robotic capping system that can be used with any screw cap. The torque is adjustable, and the capping area is made of soft silicone, effectively protecting the cap during operation.

Technical Parameters

SJ600: 60 bottles/minute (filling and capping integrated)

Suitable Sizes:

Minimum Bottle Diameter

10mm Diameter, 50mm Height

Maximum Bottle Diameter

80mm Diameter, 200mm Height

Filling Volume

1-400ml

Filling Accuracy

≤ ±1%

Supporting Motor

220V/50Hz, 1.1kW