Description

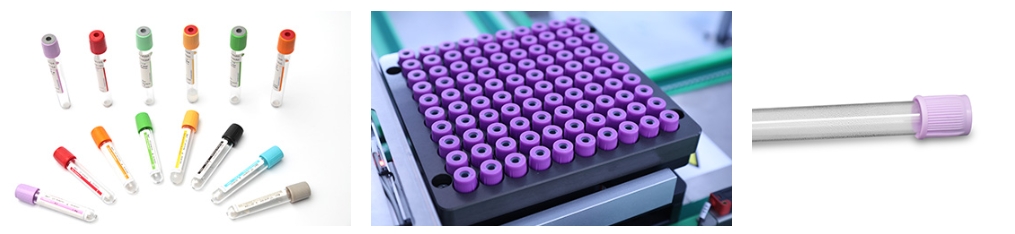

Product Description

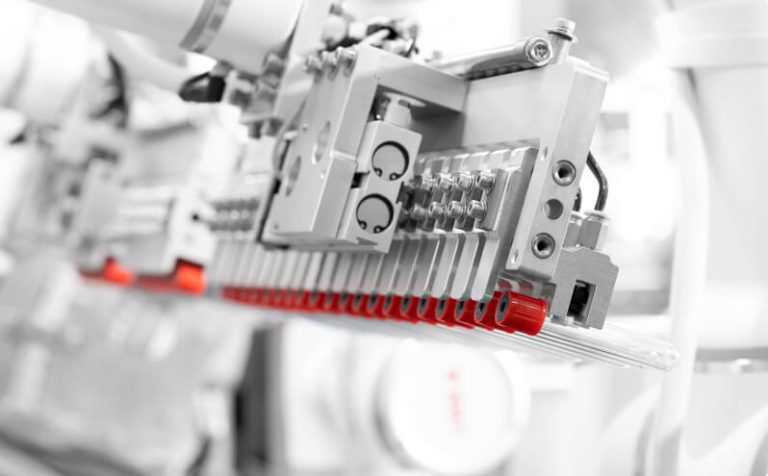

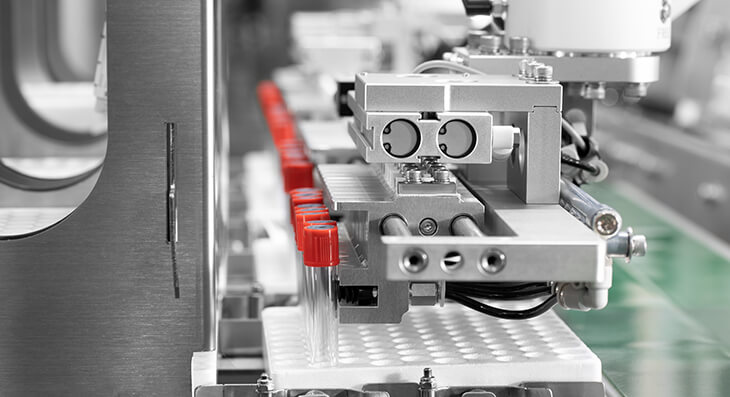

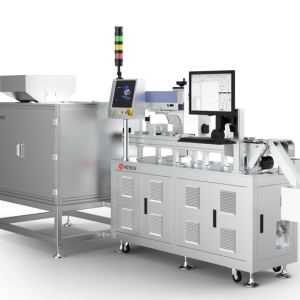

Tail-labeling machine connection online, non-label tube to be auto detected by world leading image technology after stoppering & capping and vacuuming. CCD also include rift of stopper or cap or tube, foreign matter inside tube, no additive, less additive, etc.), qualified tube transfer to tail-labeling machine and disqualified tube to be rejected. Fully auto detection technology for BCT is on the cutting edge of the industry.

Product Process

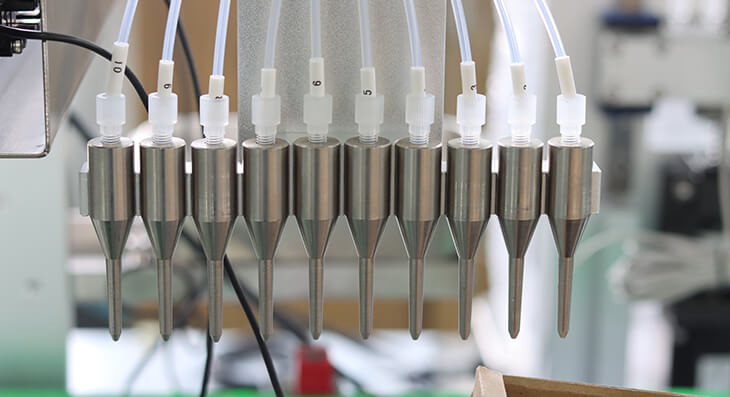

The intelligent blood collection Tube assembly line consists of several key components, including a tube forming machine, rubber stopper insertion machine, vacuum generator, cap pressing machine, quality inspection machine, and packaging machine.

Product Features

Save labor cost by equipping fully auto CCD detection, only 2-3 skilled workers can reach production capacity of 18000-24000pcs per hour. Manual tube loading only requested at the very beginning, the other stations all auto with online BCT image and online labeling inspection which rejects disqualified tubes intelligently to ensure 100% pass rate.

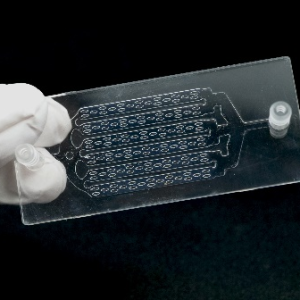

Reduce secondary pollution risk by less exposure during production, better protect the tube cleanness. (PET tube produced in Class 100,000 clean room workshop), worker only contact tube one time when loading tubes into auto loading machine, ensure tube cleanness during production in Class 100,000 level clean room workshop.

Testing qualified products for automatic labeling, ensure packaging sequence according to barcode numbers Packaging sequence according to barcode numbers can be up to export standard and usage requirements of large hospitals.

Auto inspection device rejects disqualified tube when no label, slanting label, poor adhesive label, etc., which ensures labeled tube and finished tube with pass rate 100%.

Labeling speed matches the auto assembly line speed well to ensure whole line production capacity reach 18000-24000pcs/h.

Application

The intelligent blood collection Tube assembly line is widely used in hospitals, blood banks, diagnostic laboratories, and other medical facilities. It is an essential piece of equipment for the production of high-quality blood collection tubes.