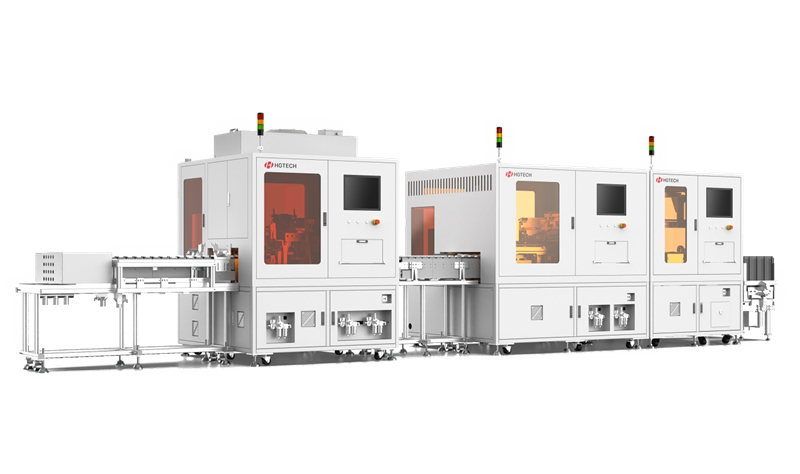

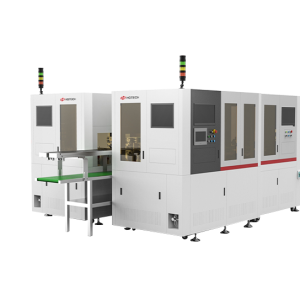

Description

This power adapter packaging line mainly realizes four functions: automatic loading and unloading, automatic encapsulation and plastic sealing, automatic tray labeling, and automatic unloading and boxing. The capsule module design adopts servo push rod drive, which precisely controls the torque and position applied during the capsule process, ensuring that the product is not damaged during the capsule stage, and the capsule effect is uniform and consistent. The device is equipped with a constant temperature and humidity control system inside, which can effectively maintain the physical state of the film material, prevent the film from shrinking or expanding due to environmental changes, and further ensure the appearance quality of the product and the consistency of the overall packaging.

Equipment accuracy

±0.2mm

Equipment CT

2.5s/pcs

Equipment UPH

1500pcs/h

Product advantages

01

Adopting a self-designed servo push rod drive module, precise control of capsule position and torque is achieved

02

Automatically scan codes to read product information, upload to MES system, and trace the entire production process

03

The device is equipped with a constant temperature and humidity system inside, ensuring that the film is in a stable state in real time and ensuring the consistency of the coating effect